Aerosol and filling equipment has been part of Coster’s history since its foundation in 1963 – today Coster is the only company specialized in both filling equipment and packaging components (valves, actuators, pumps).

Coster’s machinery division is located in Pero, 10km from the center of Milan, 40minutes from Malpensa airport and 20 minutes from Linate airport.

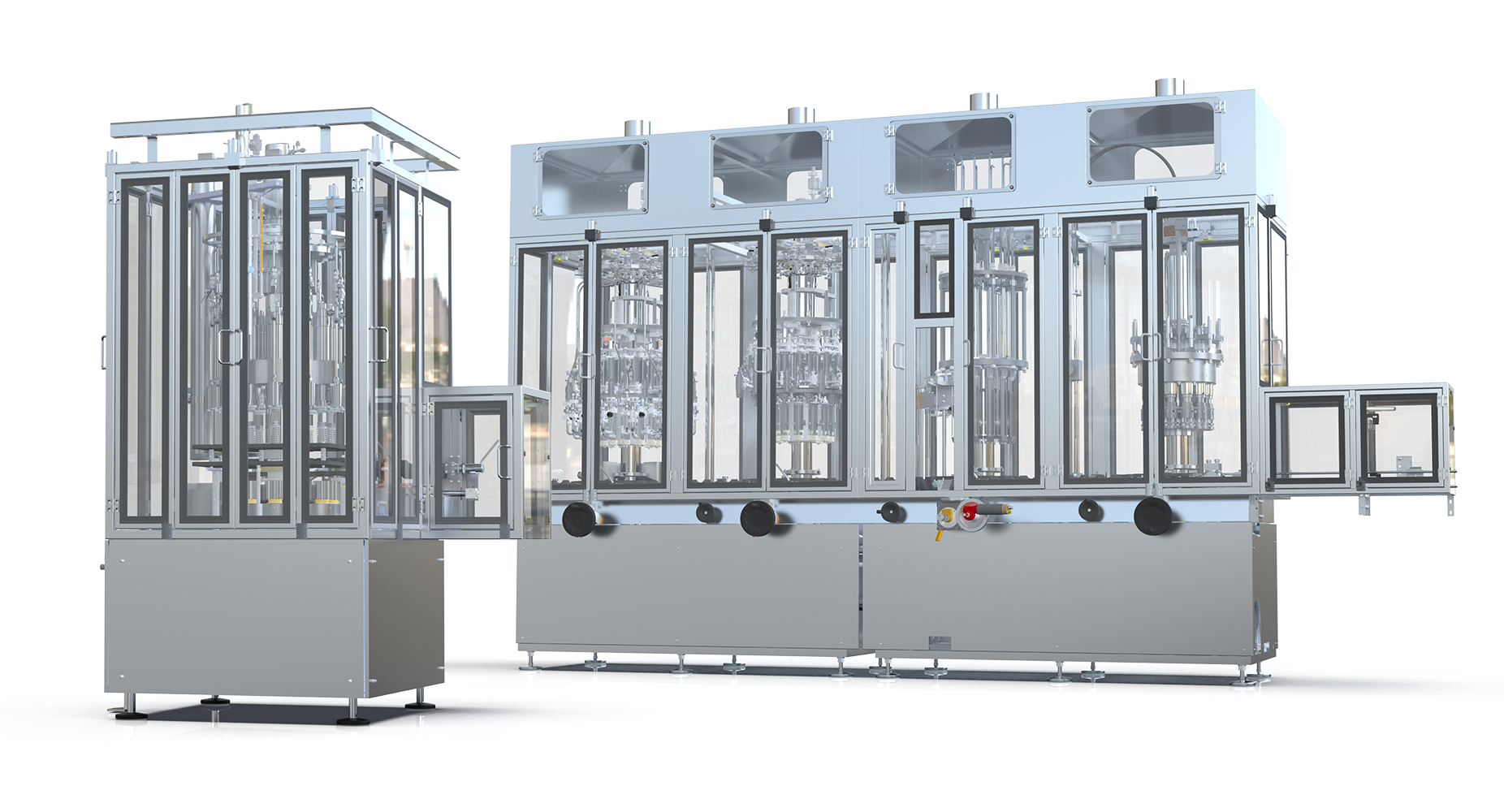

From there, it supplies filling machines worldwide, relying on a global sales and assistance network.

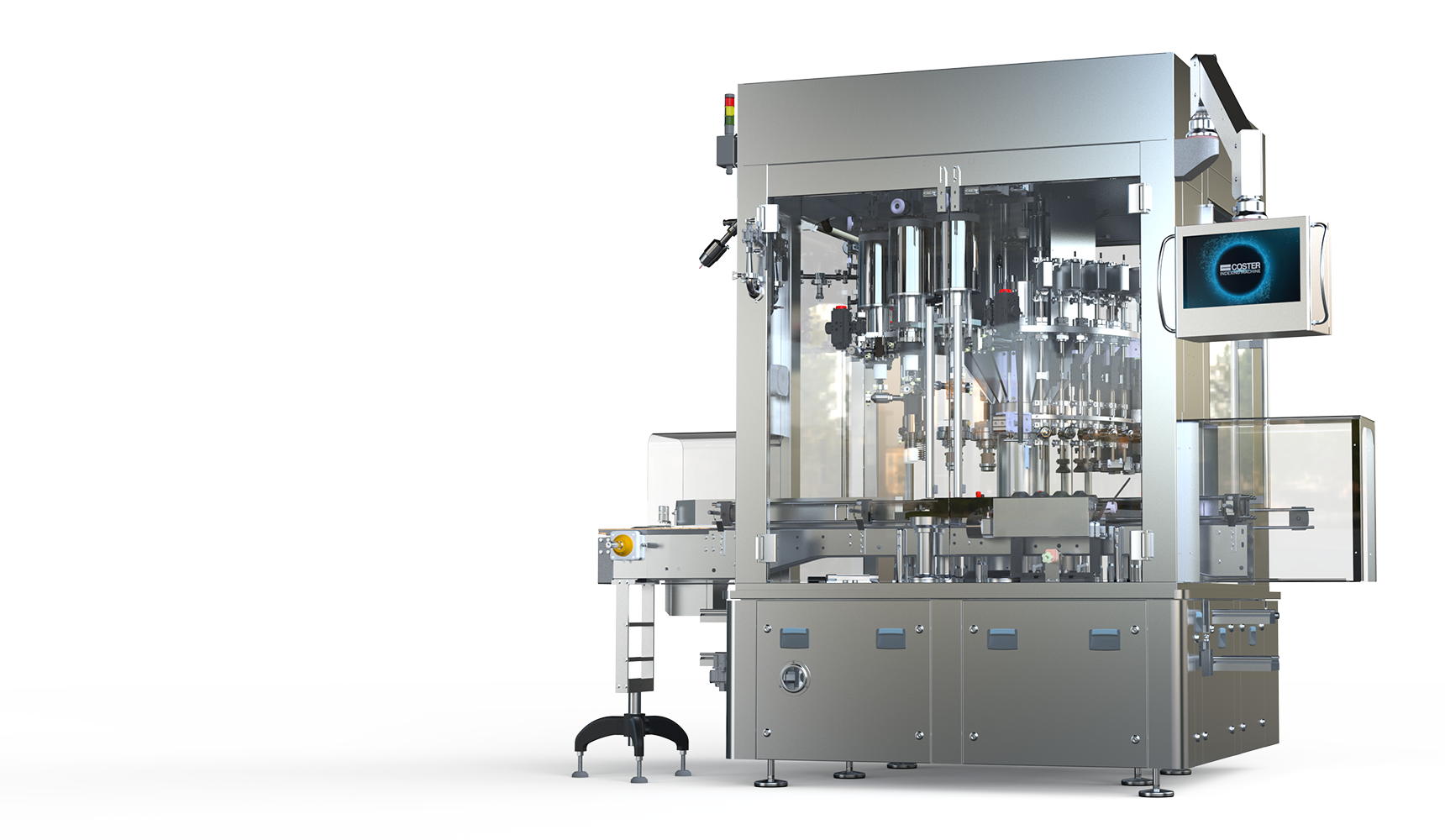

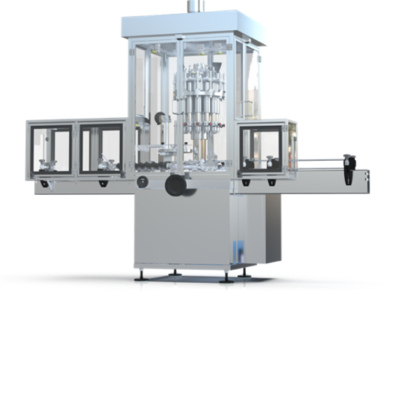

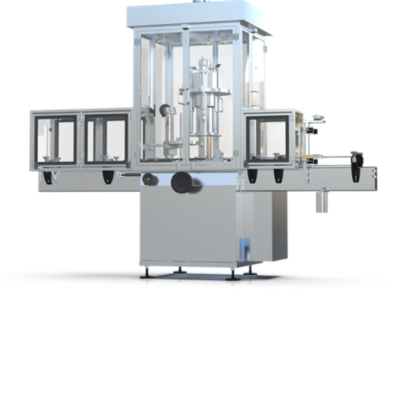

Coster’s filling machines are well known in the market for the high quality and safety standards.

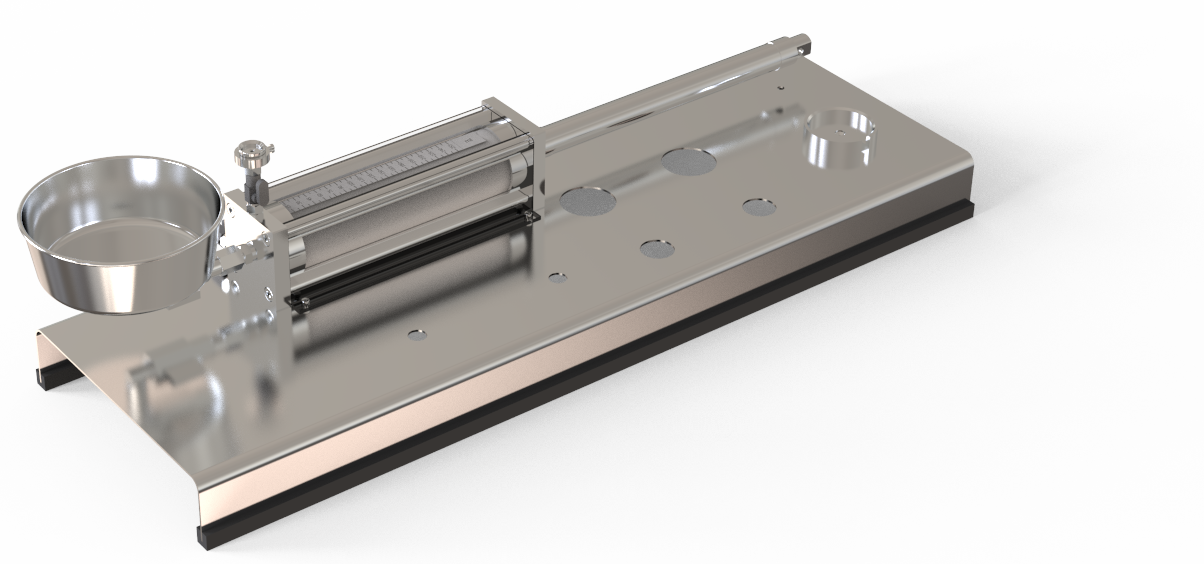

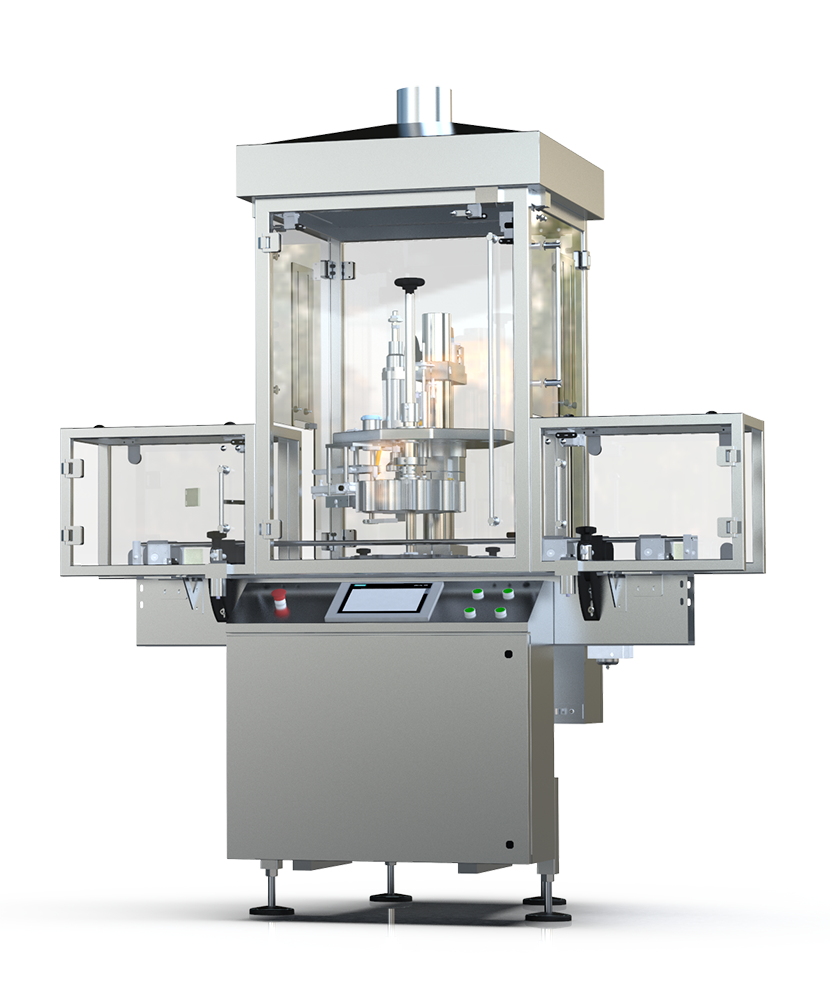

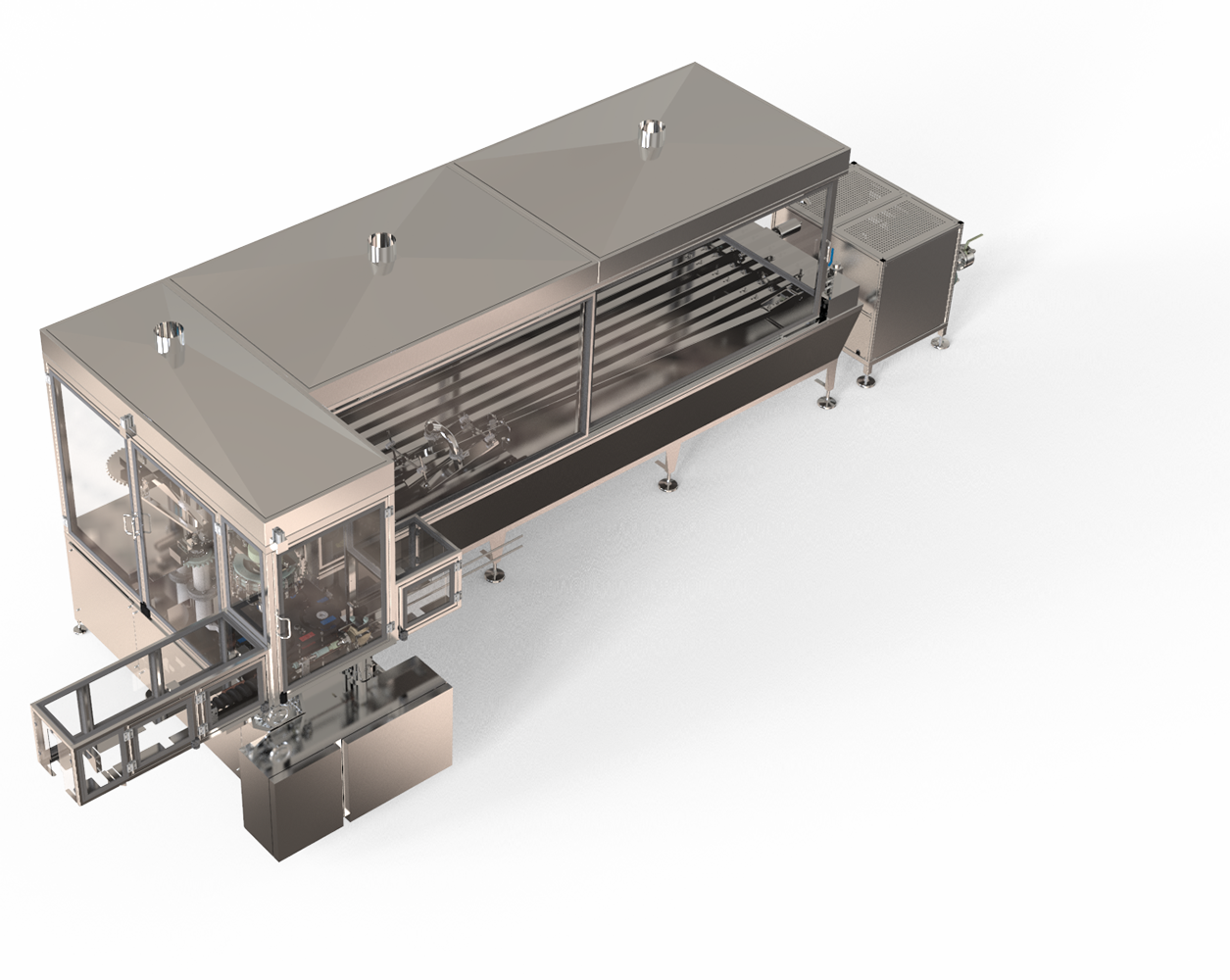

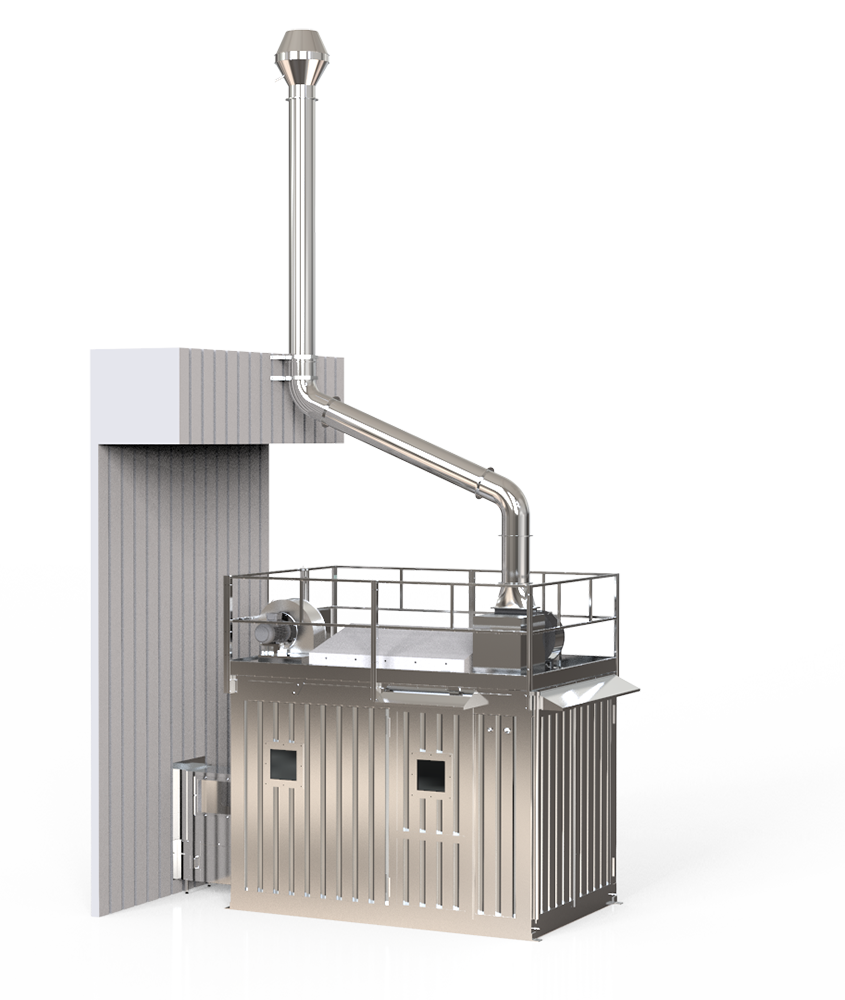

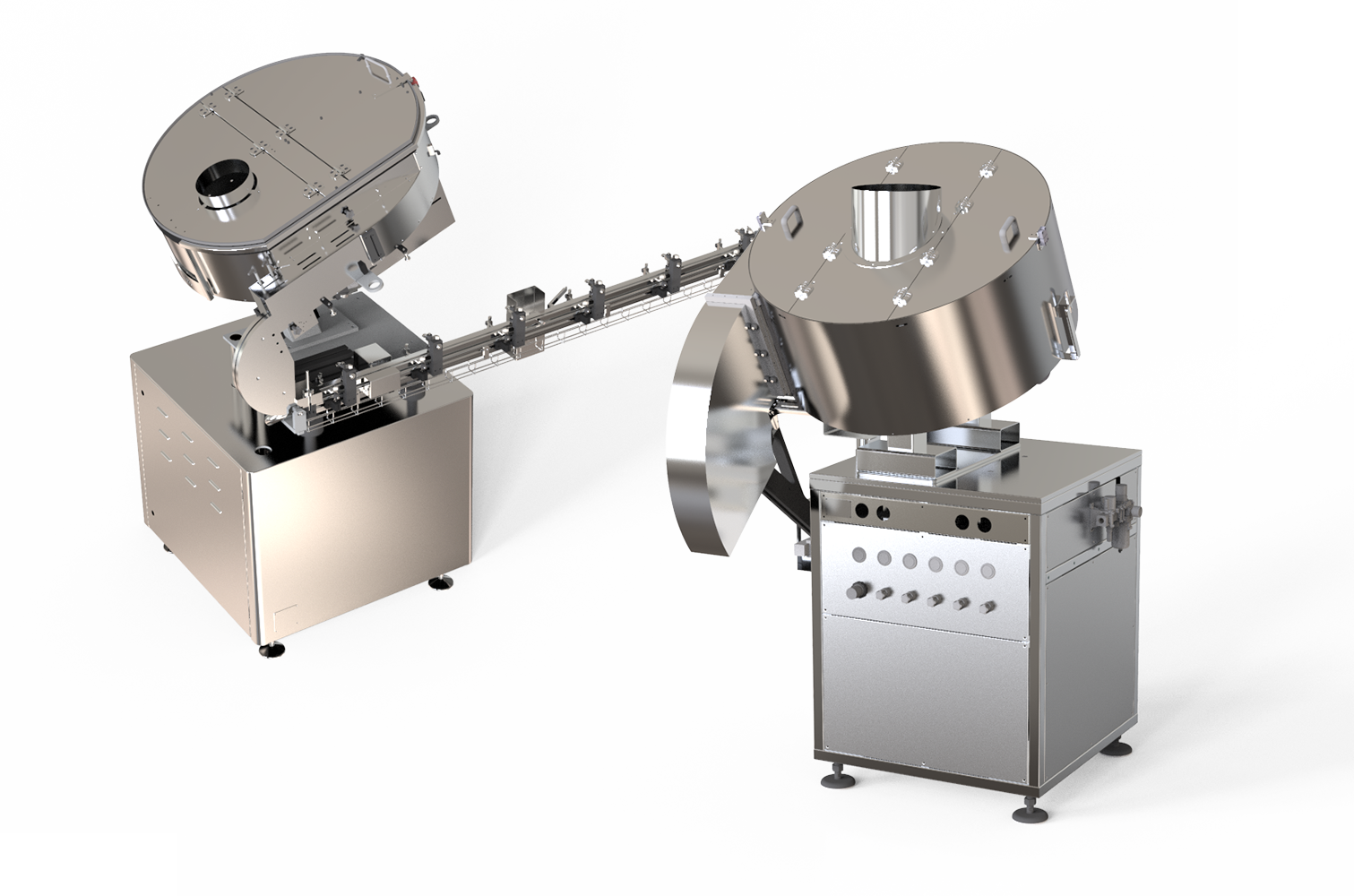

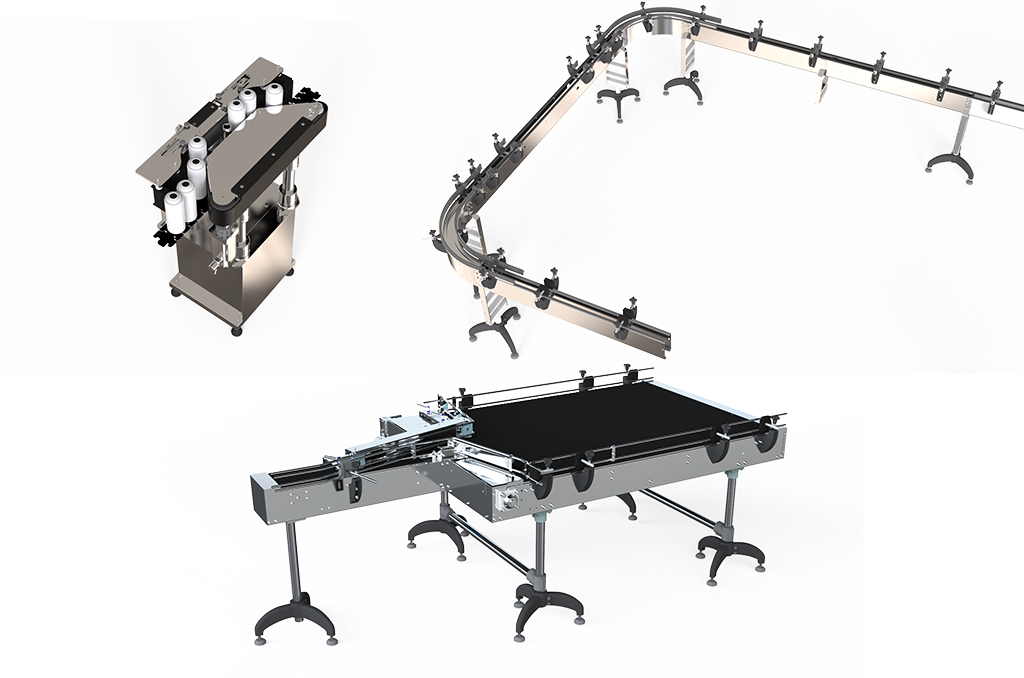

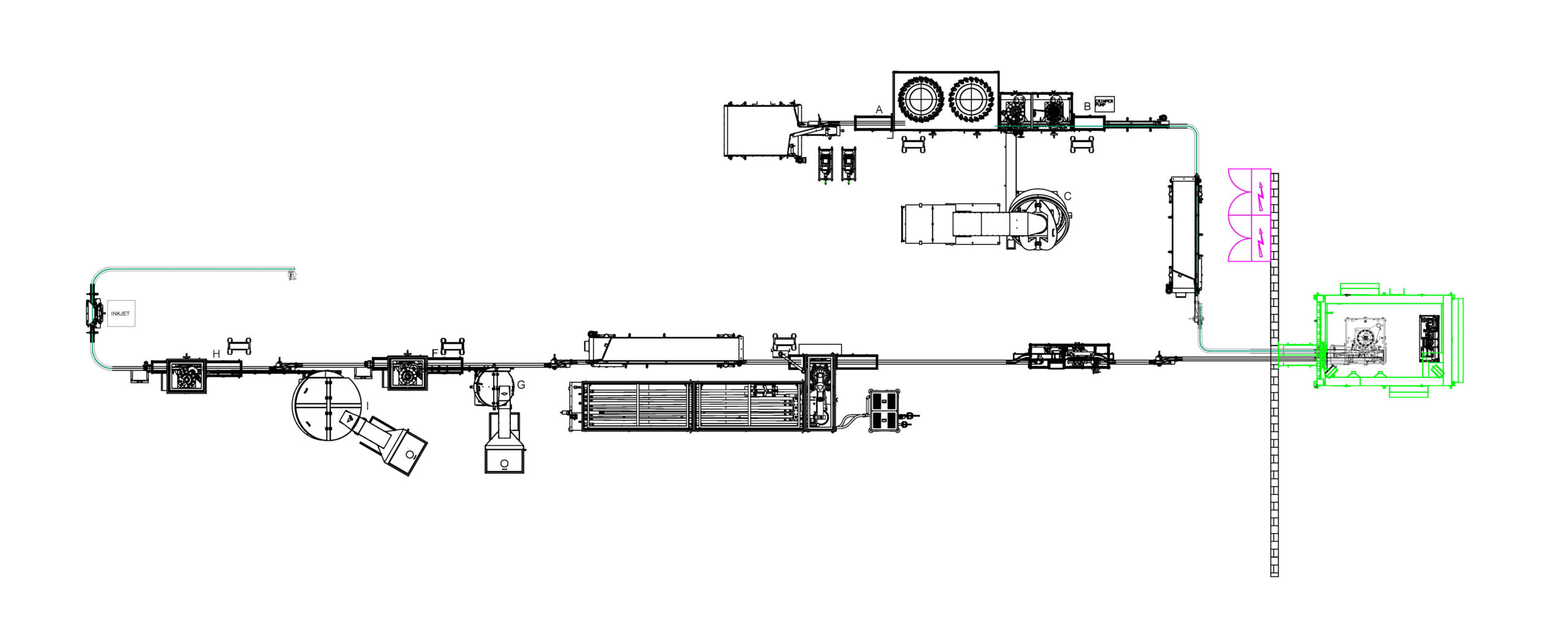

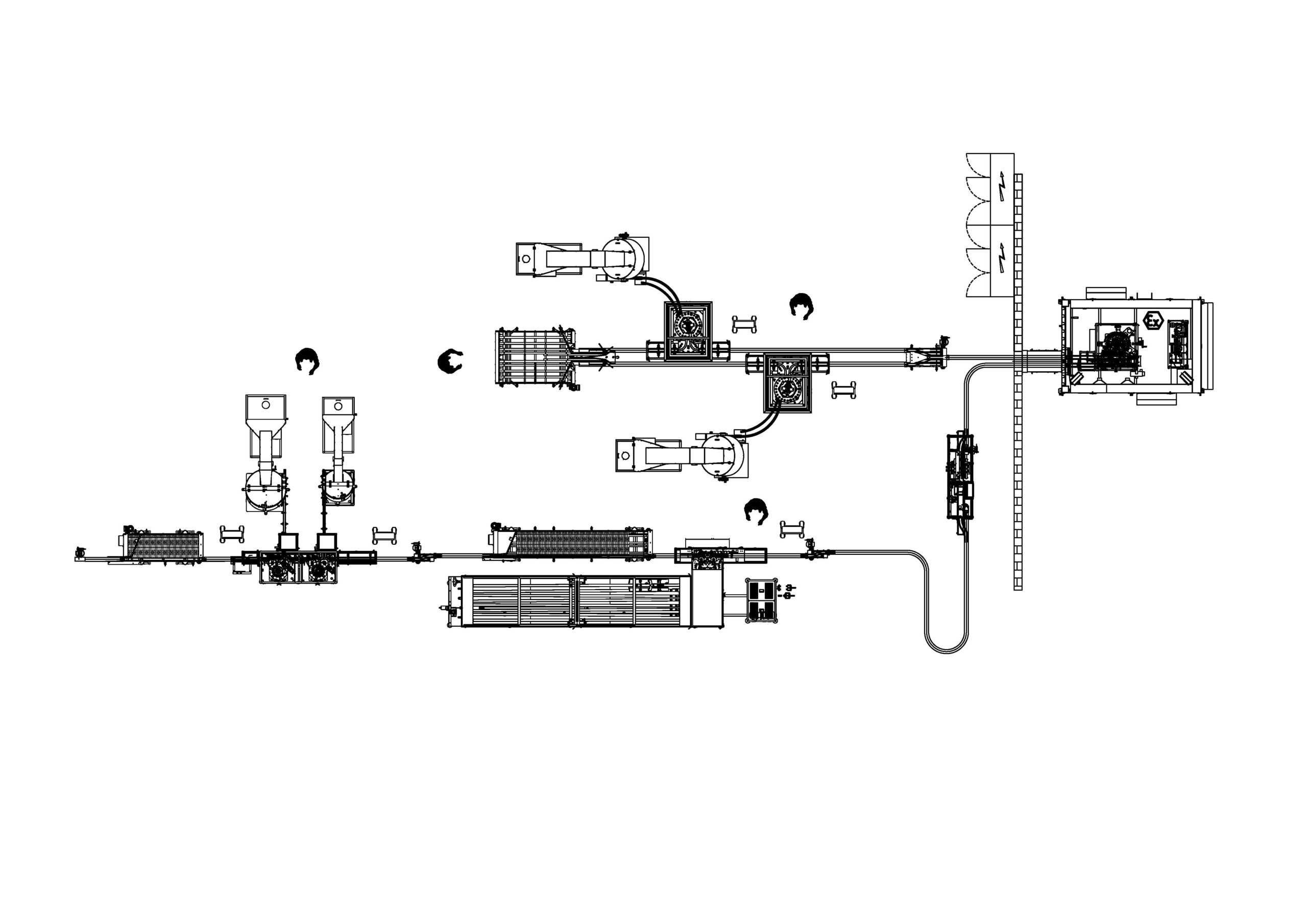

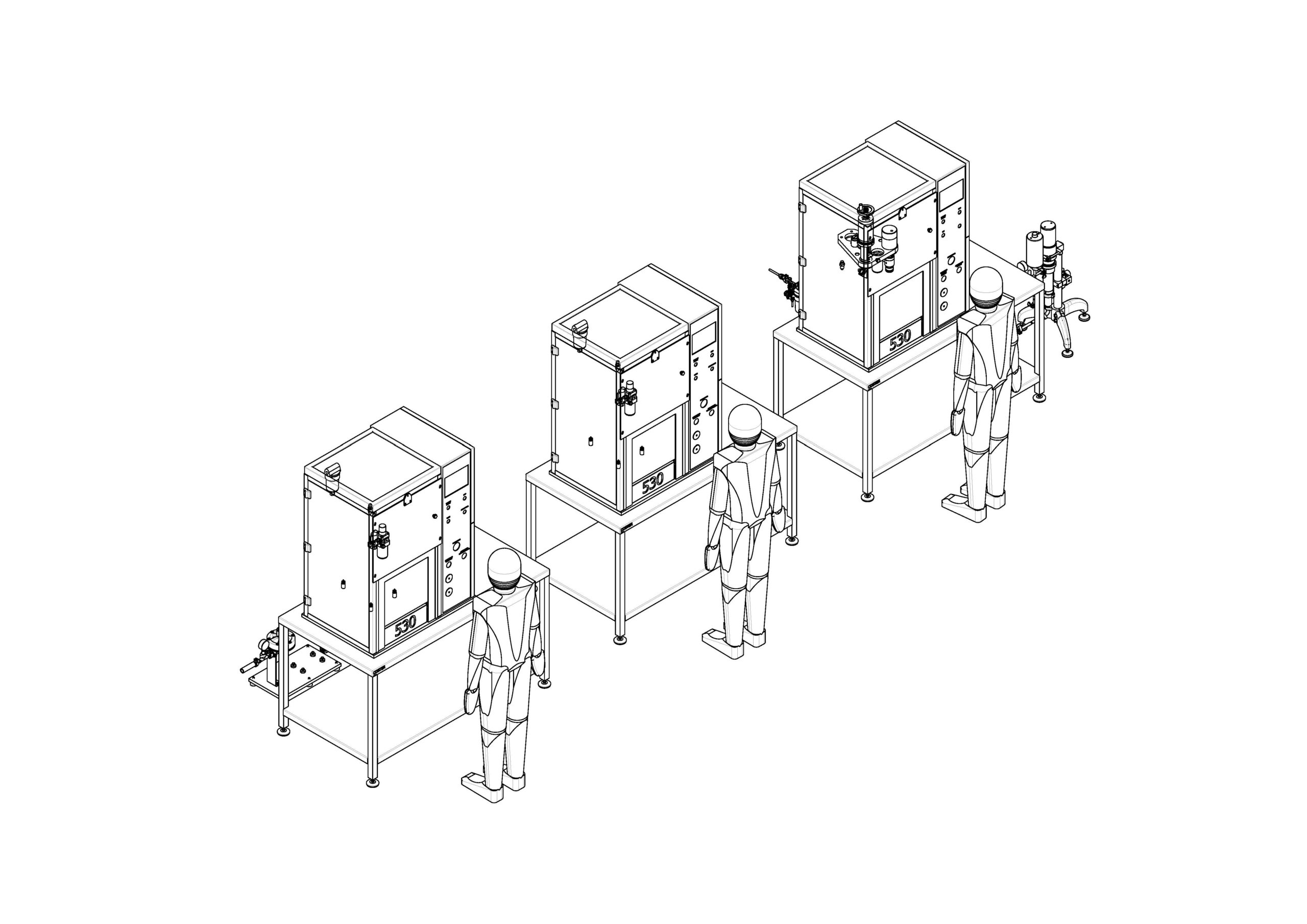

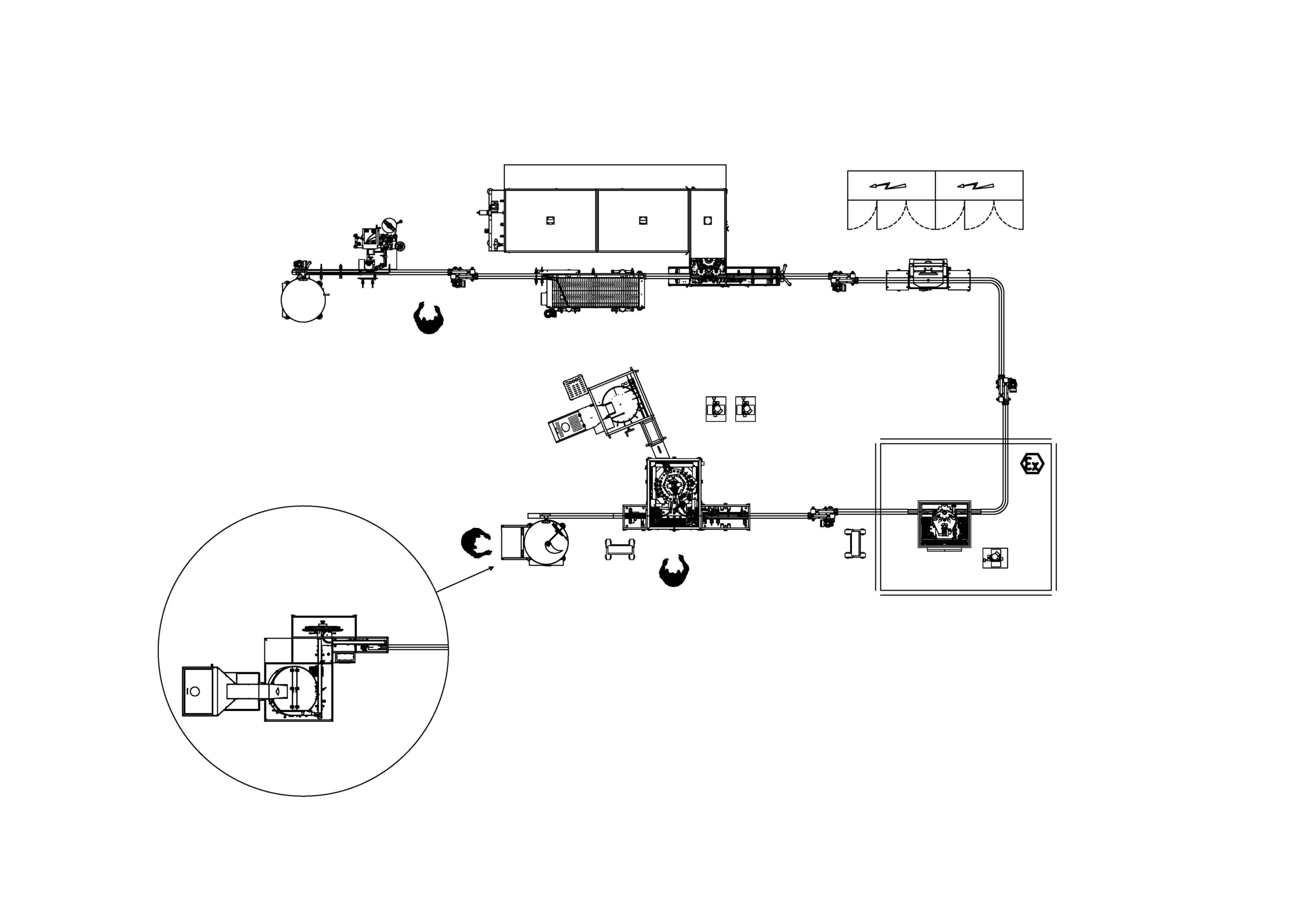

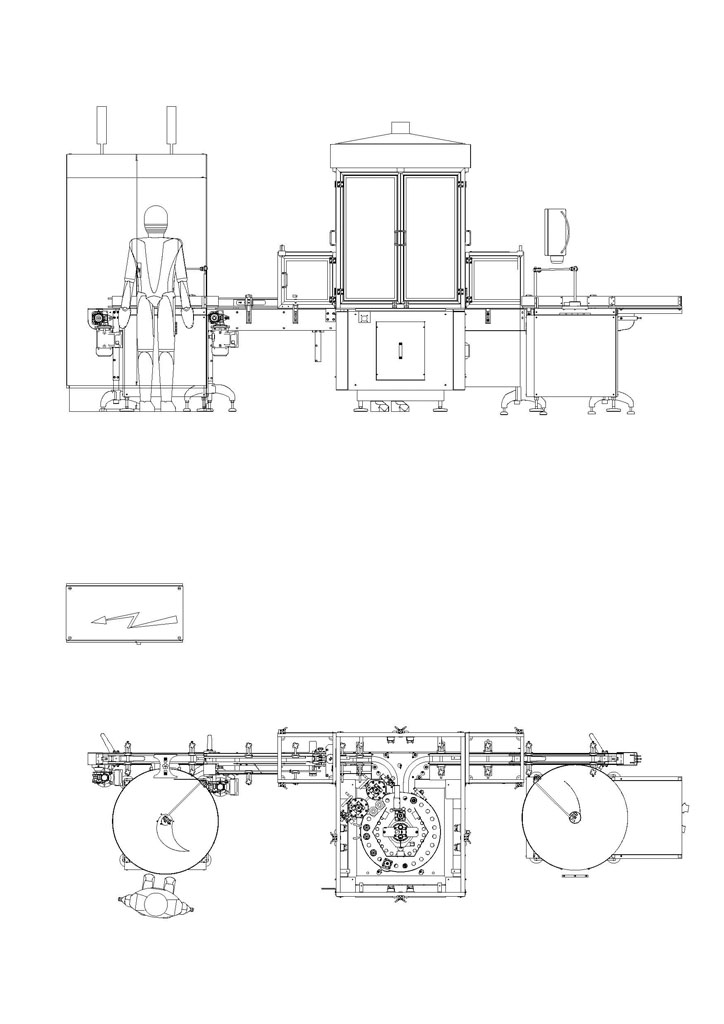

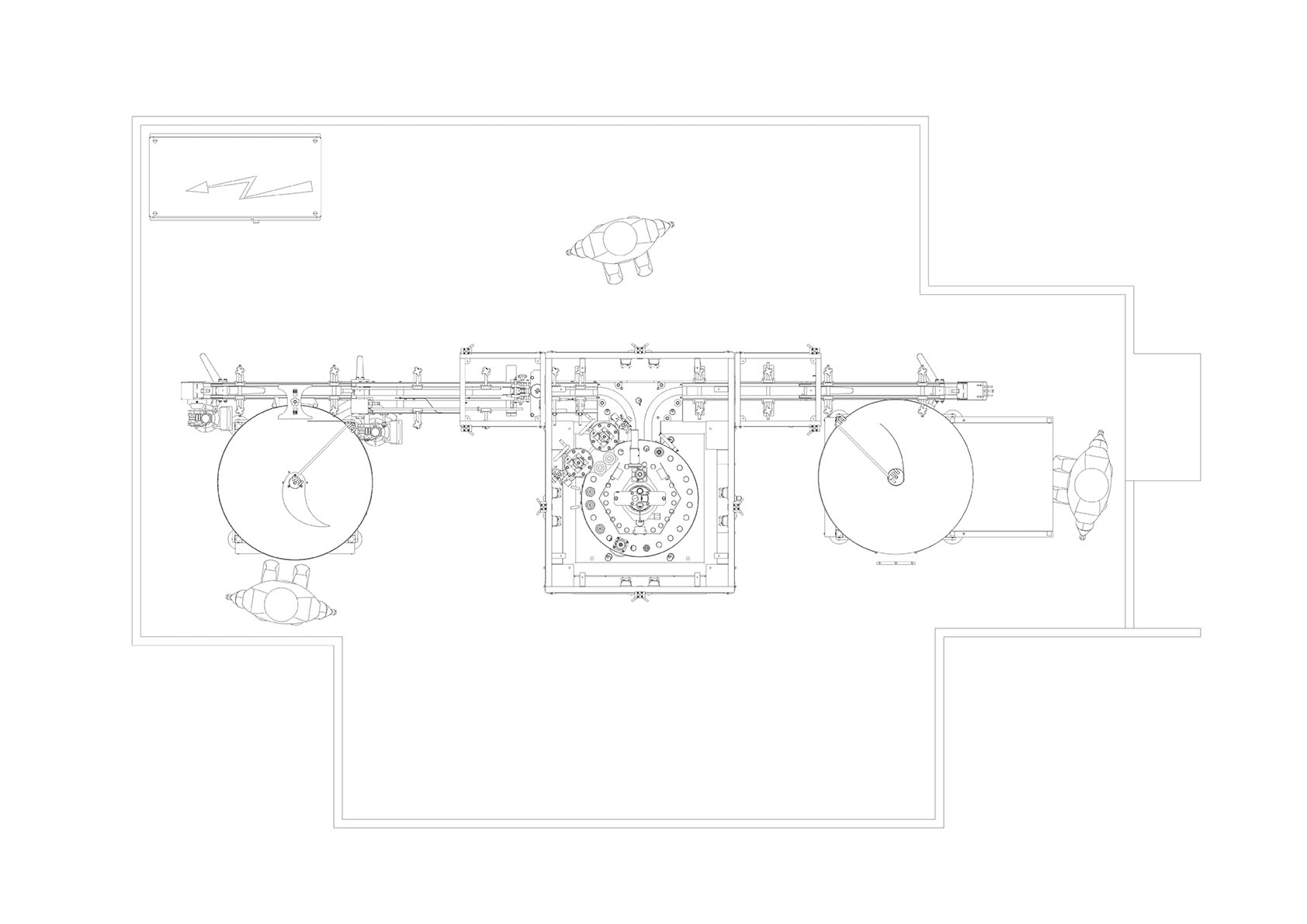

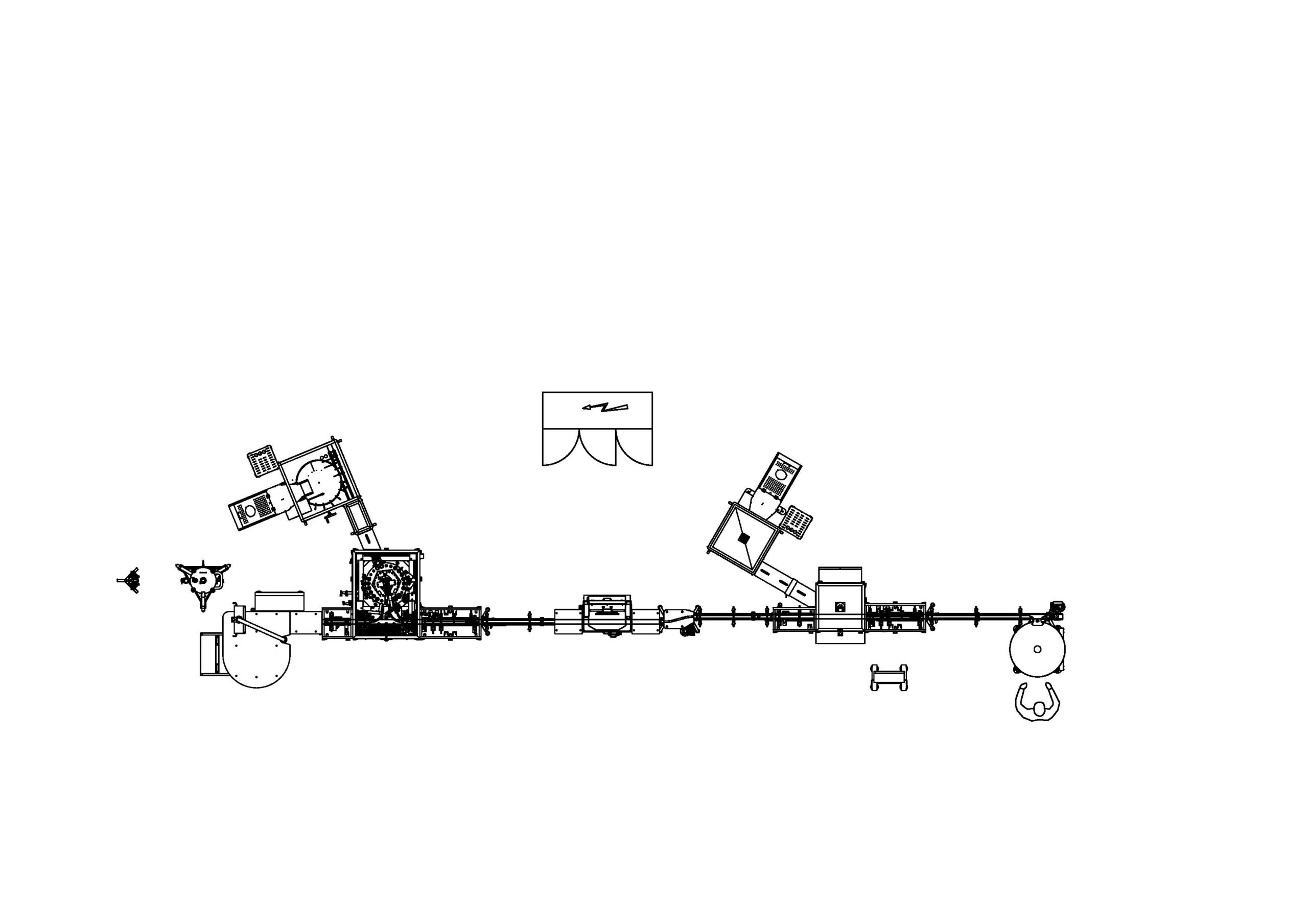

Its product offering ranges from semi-automatic machines (15/20 cpm) to fully integrated rotary lines (up to 500 cpm).

The machines are available for a variety of industries: personal care, cosmetics, household, technical.

Coster also has a range of machines dedicated to the pharmaceutical industry, such as for bag on valves and asthma inhaler valves (pMDI)